A clear vision about pure steam generation in cosmetic and biopharma environment

Pure Steam Generator for Pharmaceutical Manufacturing

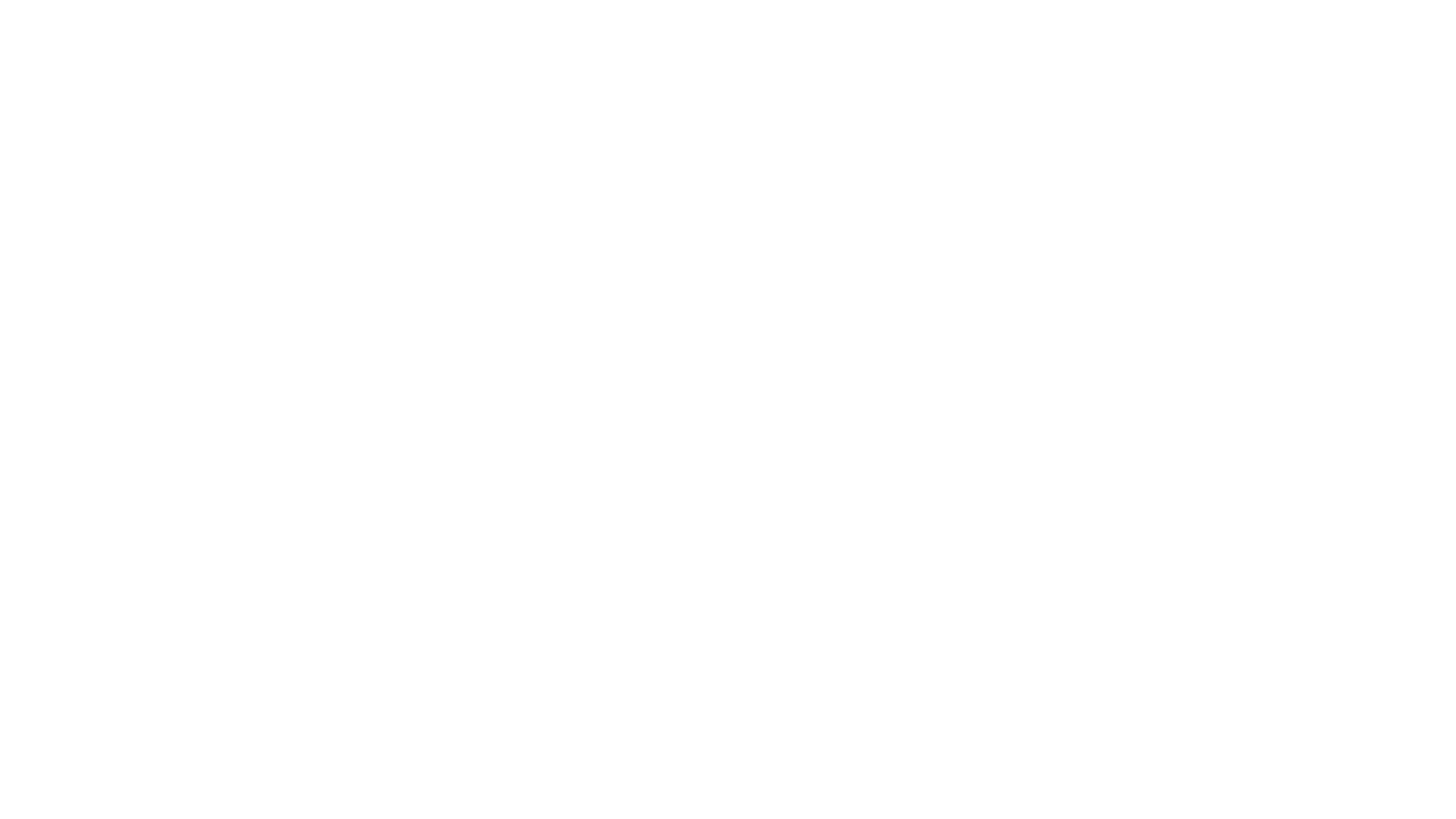

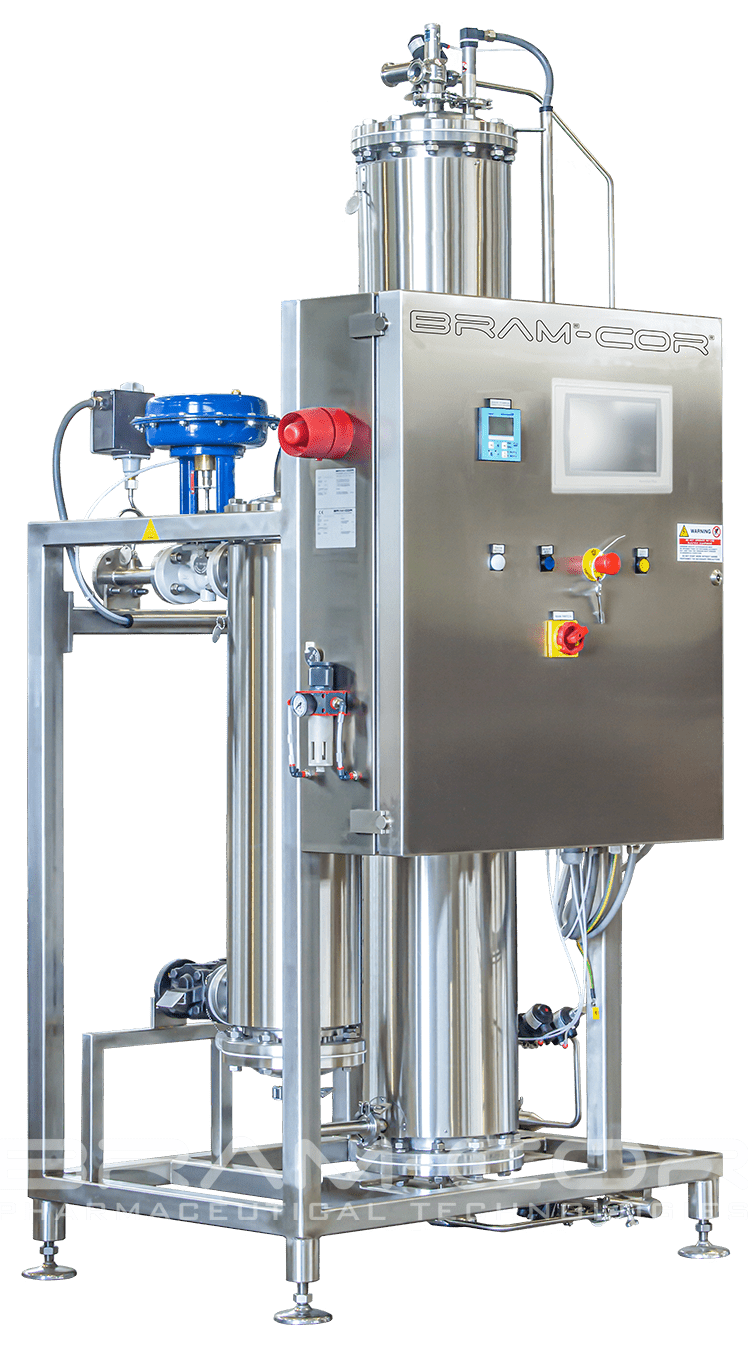

BRAM-COR CPSG Pure Steam Generators produce dry, saturated steam, suitable for sterilization of pharmaceutical production plants, for direct contact with active pharmaceutical ingredients, for parenteral and non-parenteral dosage form applications. The steam, when condensed, meets USP requirements for Water for Injection.

CPSG – PURE/CLEAN STEAM GENERATION SYSTEMS -TECHNICAL DATA

Application

• Production of dry, saturated steam, suitable for sterilization of pharmaceutical production plants, for direct contact with active pharmaceutical ingredients, for parenteral and non-parenteral dosage form applications.

• The steam, when condensed, meets USP requirements for Water for Injection.

Control System

Functions operated by the PLC (Programmable Logic Controller):

- Input of measured values and setting of limit values

- Automatic Sequences (production, sanitization, …)

- Control Functions (PID control for valves and speed of pump)

- Alarm management and Verification of parameters

- Input of measured values and setting of limit values

- Output commands for digital and analogic values

Technology

• The unit contains one boiling column (or effect) producing pure steam. The steam is purified using centrifugal and gravity separation methods.

• BRAM-COR CPSG Pure steam Generator is available in steam, electrically operated model, or superheated water.

HMI Sytem

HMI (Human Machine Interface)

- Display of machine state

- Controls management

- Verification of alarms

- Set points inserting and limit values setting

- Graphic interface

All automation systems can be in compliance to 21 CFR PART 11 or Siemens Operator Panel, through audit management and electronic signature. Access management included (user/password).

Techn. Features

• cGMP design and construction; all product contact surfaces in AISI 316 L stainless steel.

• Jackets, frame and control board in AISI 304 stainless steel; all welding is performed by qualified welders.

• Gaskets in EPDM or PTFE or Silicone; pneumatic valves with Teflon/PTFE membranes and AISI 316 L SS polished body; ASTM C-795 – compliant insulation.

• Instruments: conductivity meter, pressure transducers, temp. probes & level transmitter.

SCADA System

SCADA (Supervisory Control And Data Acquisition) / SCADA SERVER

- All HMI values and controls

- Data historicization

- Historical alarms

- Trend and Report

- Recipes formulation / Batch

- Data backup / Restore

All automation systems can be in compliance to 21 CFR PART 11 or Siemens Operator Panel, through audit management and electronic signature. Access management included (user/password).

Optionals

• Quenched waste water collector & cooler with spray valve

• Pure Steam Condenser including conductivity instrument for measuring Pure Steam quality

• Digital Recorder

• VPN Router for Tele-assistance

Communication

Bram-Cor automation systems can virtually communicate with all network partners through maximum security protocol (Ethernet, Profinet, OPC Unified Architecture, …)

Options:

- Teleservice (malfunctions managed remotely by Bram-Cor)

- Remote Control (customer operator receives a message / a text message / a warning e-mail)

- Server-side data centralization (customer can centralize data on his service, or Bram-Cor provides it)

Capacities range: from 20 to 8,000kg/h

Bram-Cor coupled CPSG Pure Steam generators in a pharmaceutical water room, with remote SCADA control system.

CPSG Process

Reliable technology for durability and long lasting efficiency

The evaporation column is designed to minimize steam speed to avoid the entrainment of water droplets, which are separated from the steam by means of a special separator.

A Double Tube Sheet (DTS) Heat Exchanger provides heating of pre-treated feed water above the boiling temperature, generating Pure Steam which expands into the evaporation column. Heating medium in the DTS Heat Exchanger is typically industrial steam at 100 to 120 psig (6.9 to 8.0 bars).

Pure Steam pressure is maintained by an electronic control system, which modulate the supply steam.

VIDEOS FROM BRAM-COR YOUTUBE CHANNEL

You can watch our Youtube videos here to better evaluate our water treatment machines and pharmaceutical processing and formulation lines.

Full documentation

BRAM-COR CPSG documentation is composed by:

• GMP collection of plant-specific drawings, technical specifications, materials certificates, calibration certificates, hardware and software specifications, welding documentation, plant manuals (TECHNICAL DOCUMENTATION);

• DATASHEETS & MANUALS BOOK, containing all the datasheet and manuals of the commercial components (valves, instruments, pumps, etc) installed on the equipment.

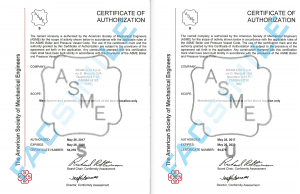

CPSG Quality range

Bram-Cor manufacturing excellence in every standard – Customized design for any application

Pharmaceutical Equipment manufacturing

Bram-Cor provides the highest quality. cGMP, PED standards and ASME S/U certification on one side and international pharmacopoeias on the other, are the baseline criteria for our design and construction. All Bram-Cor biopharma processing systems ensure full traceability, certified material and instruments.

Professional Services

Bram-Cor equipment is integrated through a proper high level of professional services including:

- Technical Documentation

- Commissioning

- Installation

- Start-up and Training

- Validation (Equipment Qualification)

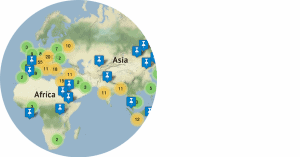

Worldwide Assistance

Bram-Cor machines are delivered all over the world and are supported by Bram-Cor After Sales service. Bram-Cor worldwide network ensures assistance in over 50 countries, from the very beginning of a pharmaceutical project and for decades after start-up. Bram-Cor After Sales dept. provides punctual and quick deliveries of spares and ongoing technical support.

WFI and Compendial waters

BRAM-COR engineering focuses on liquid / sterile drug and low / medium / high viscosity production processes, such as parenteral solutions, oral solutions, ophthalmic and oncology solutions, low / medium / high viscosity emulsions, cosmetic preparations. Purified Water (PW) and Water for Injection (WFI) are the obligatory basis of many pharmaceutical preparations.

Bram-Cor Catalogue

Pharmaceutical Equipment

BRAM-COR Pharmaceutical Equipment General Catalogue. In this thirty-six pages brochure, you can discover “at a glance” BRAM-COR systems and plants.